Digital P&ID: Future of Process Safety & Engineering Information

Add Your Heading Text Here

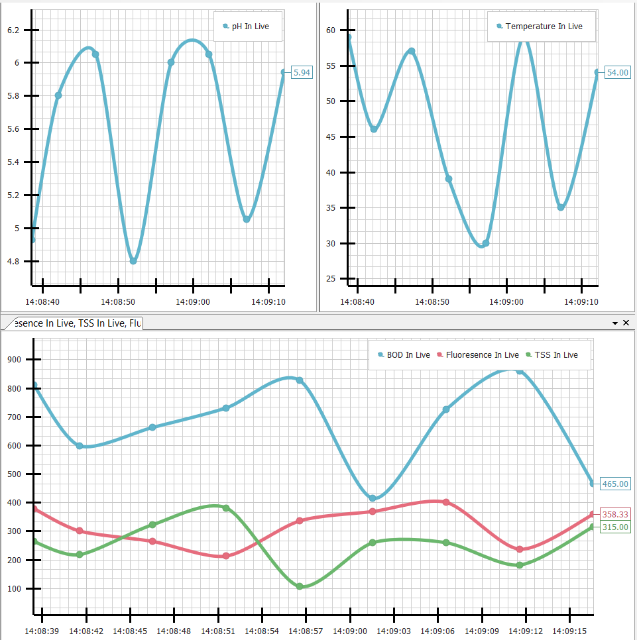

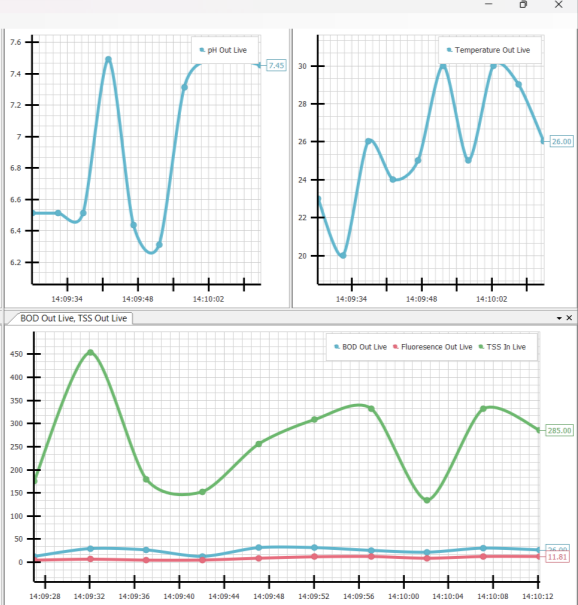

In process industries, data is critical for making any informed decision such as optimizing processes, improving product quality, reducing costs, and implementing safety. However, one of the biggest challenges that process industries face today is the lack of data or the inconsistency of data.

P&IDs: Importan

Used for:

a. Management of change (MOC)

b. PSM Studies

c. Risk Mgmt & Mitigation

a. Process engineers

b. Designers

c. Operators

d. Maintenance

e. Safety personnel

© Sparrow Risk Management Pvt. Ltd.

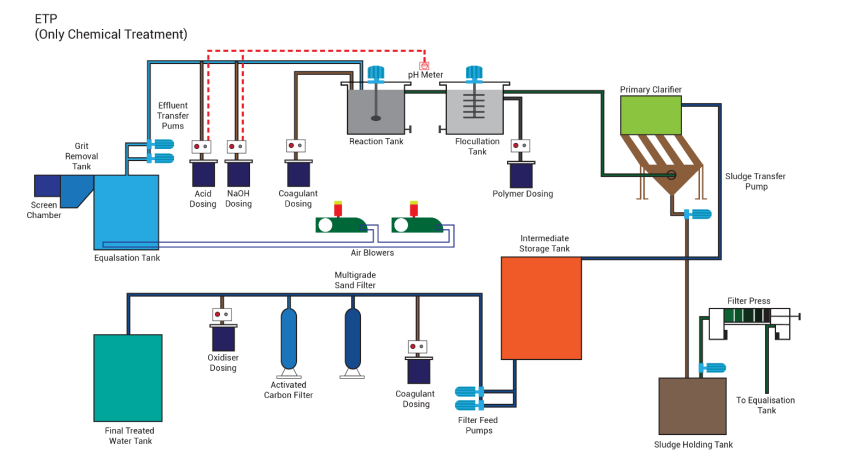

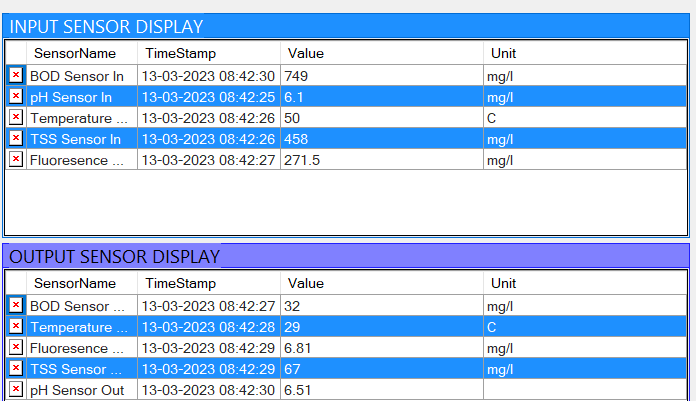

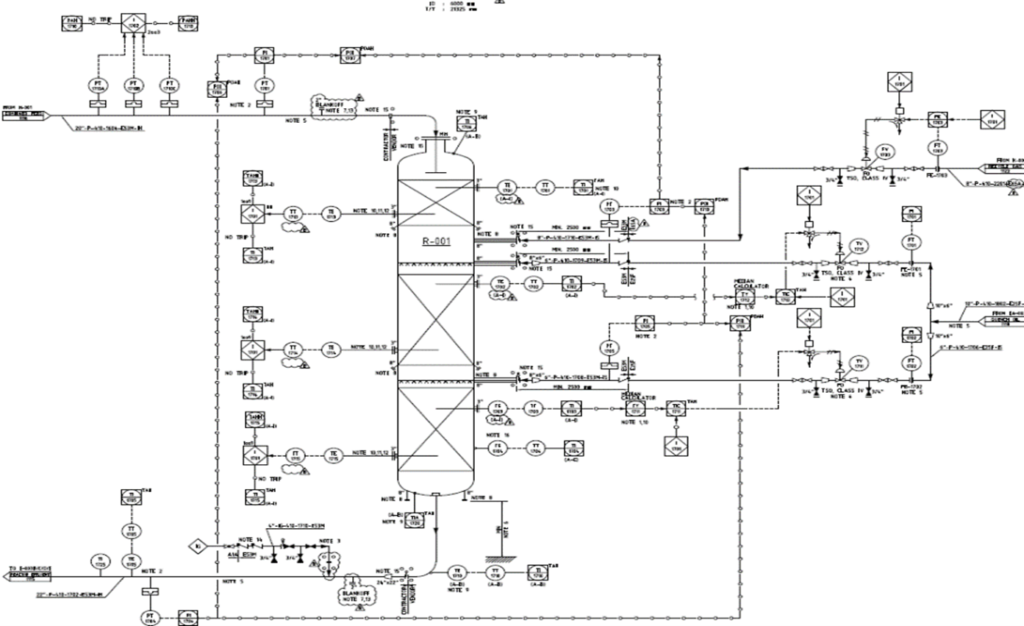

Conventional P&ID have not evolved over the period of years and retain their legacy approach towards focussing on only conveying the process flow, key components (equipment and instrumentation) and detailing of I/O.

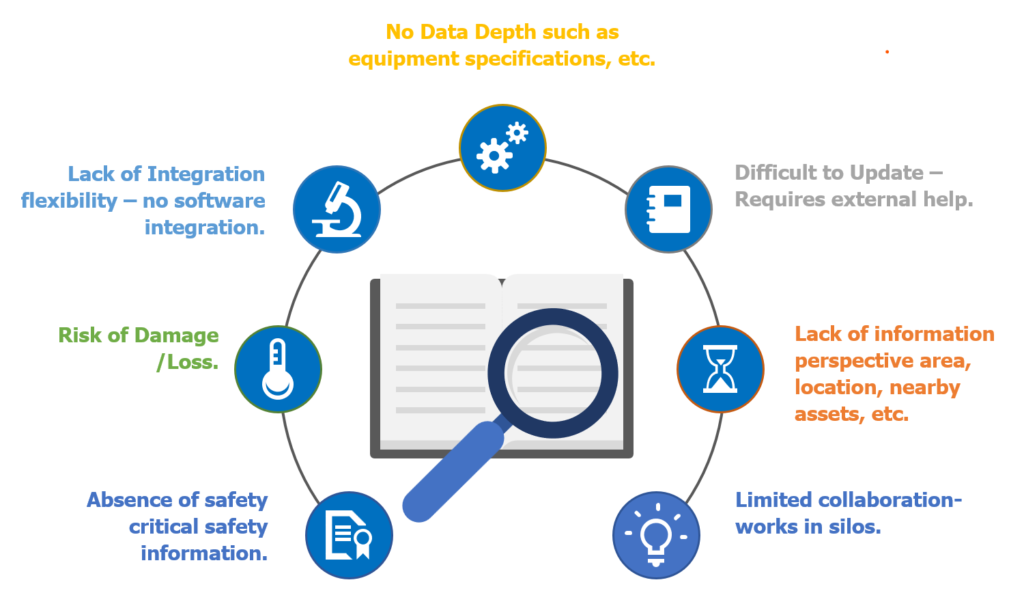

Limitations of Conventional P&IDs:

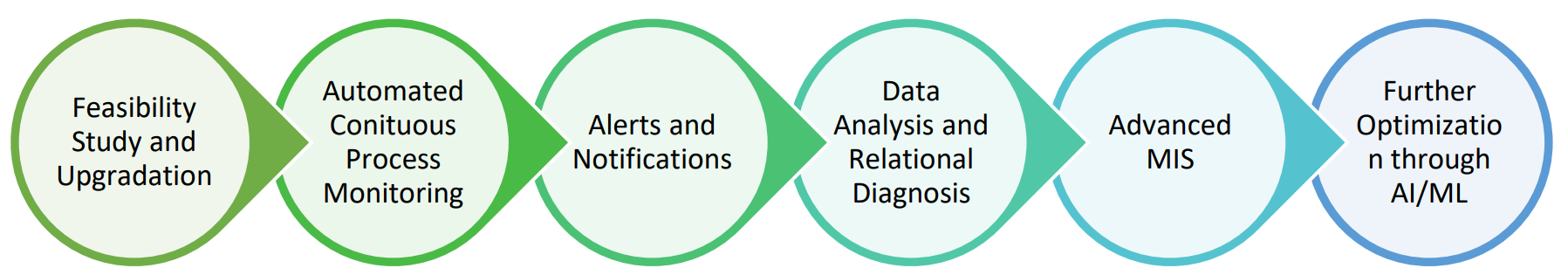

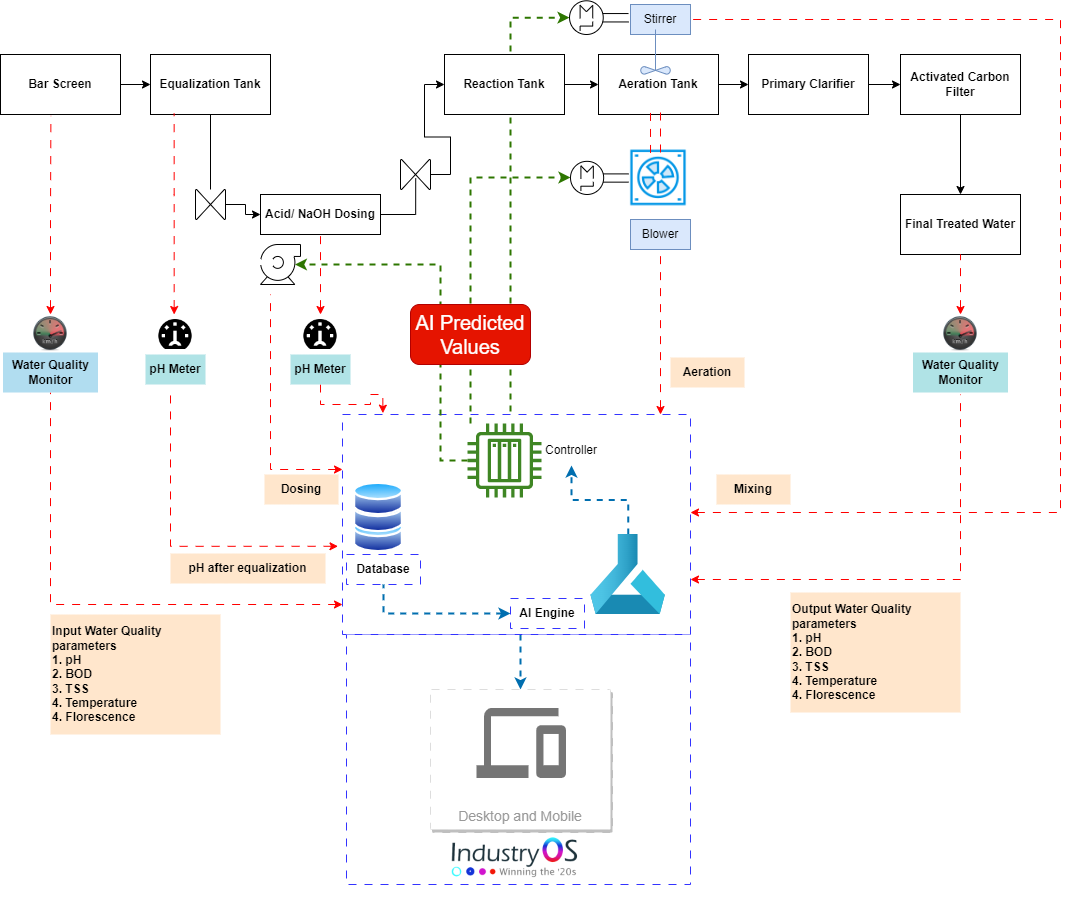

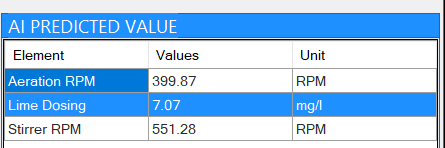

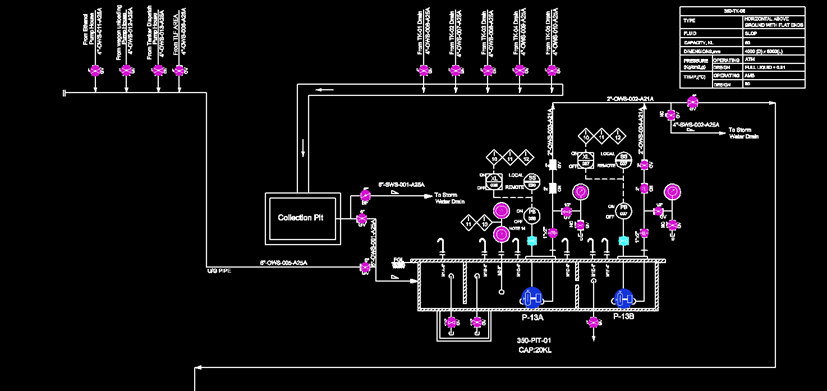

Digital P&ID has all the elements of a conventional P&ID backed by a layer of data with software integration.

© Sparrow Risk Management Pvt. Ltd.

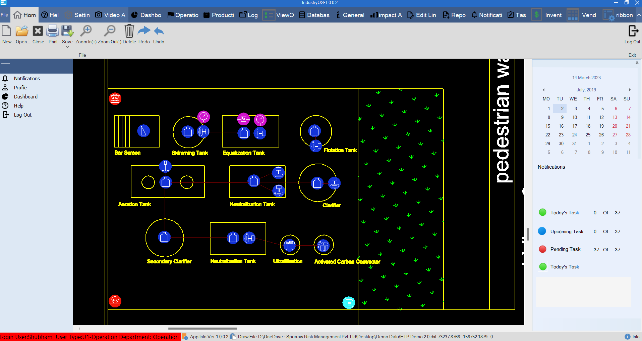

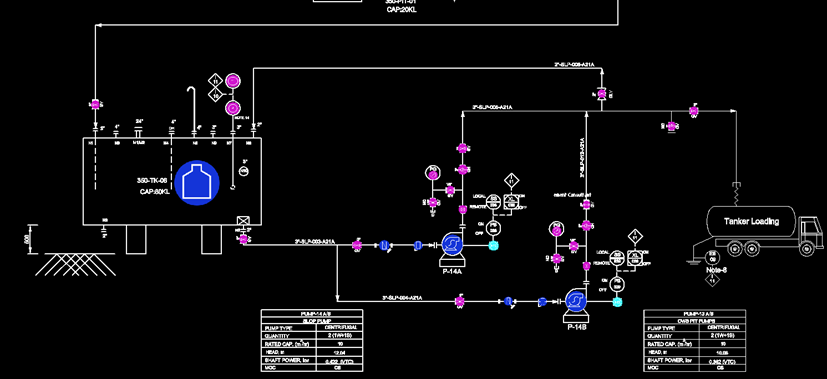

Digital P&ID, based on the concept of iLOL™ (Information Layered over Layout) creates an exact replica of the process on the overview of the plot plan of the site through Digital Twinning. It has all the elements of a conventional P&ID backed by a layer of data.

Digital Twinning through iLOL™:

iLOL™ - Information Layered Over Layout.

iLOL™ is a 2D Digital Twin Technology innovated by Sparrow to represent your premises in digital environment, exactly the way you see your plant/factory – which then uses layers of information creating a data lake of all machine and process information.

The information data covers all possible elements:

- Machines

- Connections

- Equipment Specifications

- Process

- Specific Maintenance & operation data

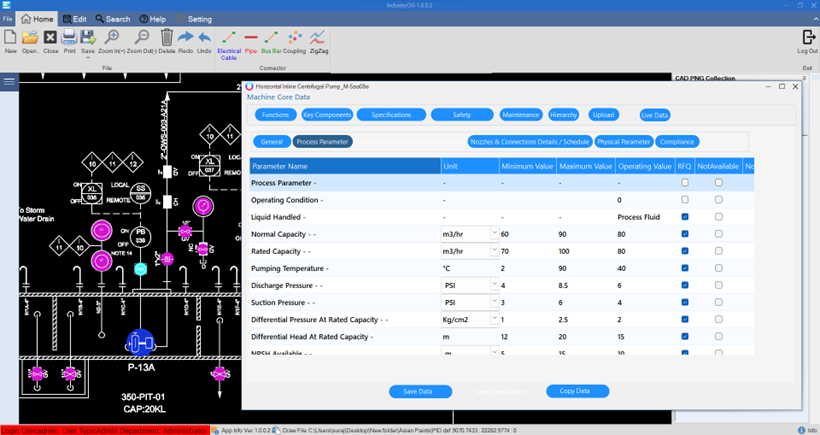

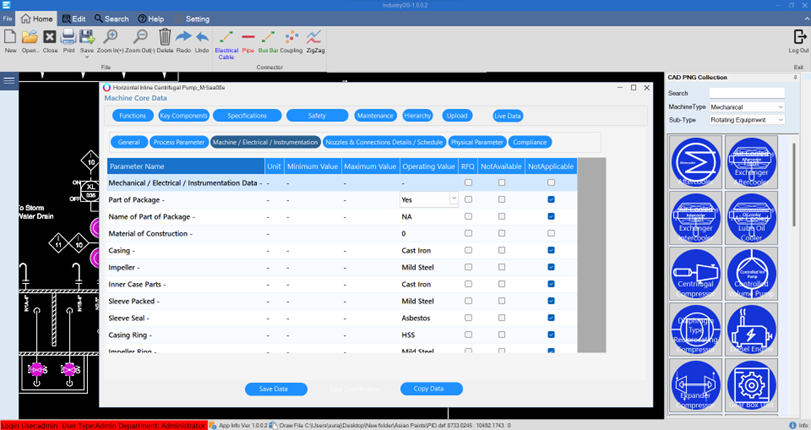

Each icon is an equipment that is modelled as an ANSI database. The equipment can be dragged and dropped, and connections can be created at ease with every connection type such as piping, electrical or mechanical.

The data depth is detailed and exhaustive to include:

- Detailed design specifications.

- Max and Min operating values.

- Instrumentation

- Safety Components

- Process Hazards

- Risk Assessment Scenarios

With a library of over 5200+ assets of different classes, IndustryOS™ can build any P&ID across various industry segment and most complex processes.

Benefits of Digital P&I:

Visual Connect

Exact equipment location (area wise) (adjusted to one elevation level)

Increased Safety

Data depth enables risk assessments such as HAZOP, LOPA, etc.

Enhanced Collaboration

Update and share easily, ensuring up-to-date info.

One Version of Data

Process & major parameter of equipment and instruments in a single click.

Seamless Integration

Integrate with other software tools.

PSM Foundation

Data foundation layer for – Risk Assessment, MOC, PHA, etc.

Process Safety Information

© Sparrow Risk Management Pvt. Ltd.