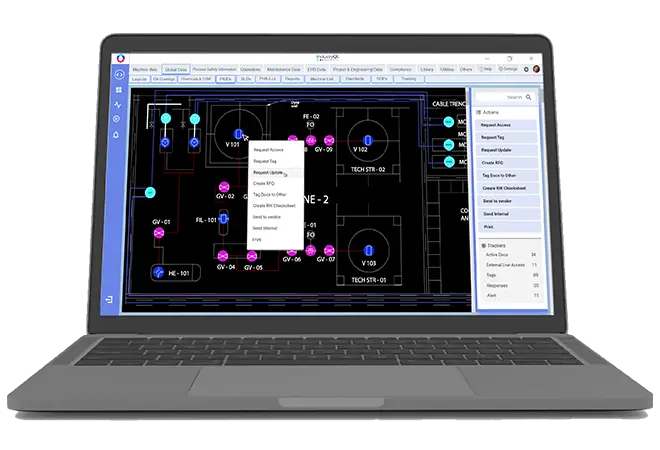

that utilises CAD layout and AI in background.

Scalable to all IndustryOS modules, smart workflows

and IOT capabilities.

Intelligent Data Manager

Subscribe to Our newsletter to stay up to date with all the latest news in EHS, Industrialization & Technology.

What is IndustryOS ROCK?

IndustryOS Rock is future ready data management ERP for factories, building, warehouse infra, made up with the most intuitive fundamentals of iLOL (information over layout). It is as simple as if you are at the site to access the data. The depth of information is humongous – machines (all specification data, maintenance, process, RFQ, Vendor few to count), Process (all process data & interconnection manages SLD, P&ID level data), People (KPIs, human cassette information), layout specific data such as overlayed QRA output, production zones, tag areas perspective storages etc. – it enables one version of data across global network, updated information to all, selective selection securely with RFQ, Vendors, Consultants too)

- On Cloud & in premises – as asked

- Global access

- Machine (all type of infra) and other elements – Drag & drop

- No limit scalable – objects, IOT, Data Analytics, AI, Machine learning,

- Scale to workflow management all 3 functions, integrated sensors and Industry 4.0 requirements.

Explore Rock Benefits

Choose from a wide range of options to adopt – it’s a journey which can start from a Process data ERP and further can be enhanced with Mechanical, Electrical and Fire data module or, in any formation. It brings the flexibility you have been waiting for !

Features & Business Benefits of

IndustryOS ROCK

See how Rock shall revolutionize your digital journey

One version of Data

Same version of data across the organization for all departments to avoid duplicacy of data and Out dated information.

Zero time lag

Avail all data & documents with a single click.

Foundation for Digital Twin

It uses iLOL as foundation for data overlay and paves way for future digitalization.

Collabaration Platform

Collaborate internally and externally, tag data to vendors, suppliers with all security features.

Modular Machines & Composite Connections & Remote conection

All machine data with P&ID visualization incorporating all possible service connections with true data.

Controlled sharing internally & with RFQ to vendors

Enable partial sharing, links, auto expiry of shared data - no edits can be made from except internal approved team.

Scale to IOT & Indutry 4.0

Use our other modules to create workflows, Digitize processes or, even create pipe line between any other Software you may implement for other benefits.

Uniform standards across corporate and Factories

Standards look around, also prepare for global reporting - Provide your process and we shall Digitalize such as GRI, ESG, HIPAA, CIPA, SOX and other regulations require detailed and accurate reporting.

- Machine on layout

- Machine connectors

- Main Design Parameters

- Machine Specification Sheet

- Key Component

- Inventory

- Maintenance calendar

- Maintenance detailing

- Training data

- Machine Level Safety data (checklist, SOPs, HIRA, JSA etc.)

- Audit Calendar

- Existing Audit reports

- Standard List

- Document uploader (Machine & Plant level)

- Machine Engineering Data

- Production Details

- Utility Consumption data

- Compliance & risk register

- Chemical management

- Employee Hierarchy

- Work permit

- work order management system (RFQ)

- Preventive Maintenance & Breakdown Maintenance

- EHS SOPs, Risk register, Unsafe act & Unsafe condition

- Human Resource- Cassette model

Rise of Data to Practicality of Use & Analytics

Contact Us

Sparrow Risk Management, Operational Control Center, Cyber City, DLF Phase 3, Sector 24, Gurugram, Haryana 122002